Water-cooled charge air cooling

Inleiding

Charge air cooling, also known as intercooling, is an essential part of the modern combustion engine. A low intake air temperature means more oxygen and therefore lower fuel consumption. The specifically developed plate cooler with asymmetrical design brings compact size to your application.

Maximum back pressure

Due to emission requirements, a very low resistance for the turbo air circuit applies to all engines with turbos. Excessive back pressure in the intake circuit will make it more difficult for the exhaust gases to escape, which will cause combustion problems. Oversluizen has gained a lot of experience with built-in controls over the years and knows what is needed to deliver the right solution in 1 go.

Customer demand:

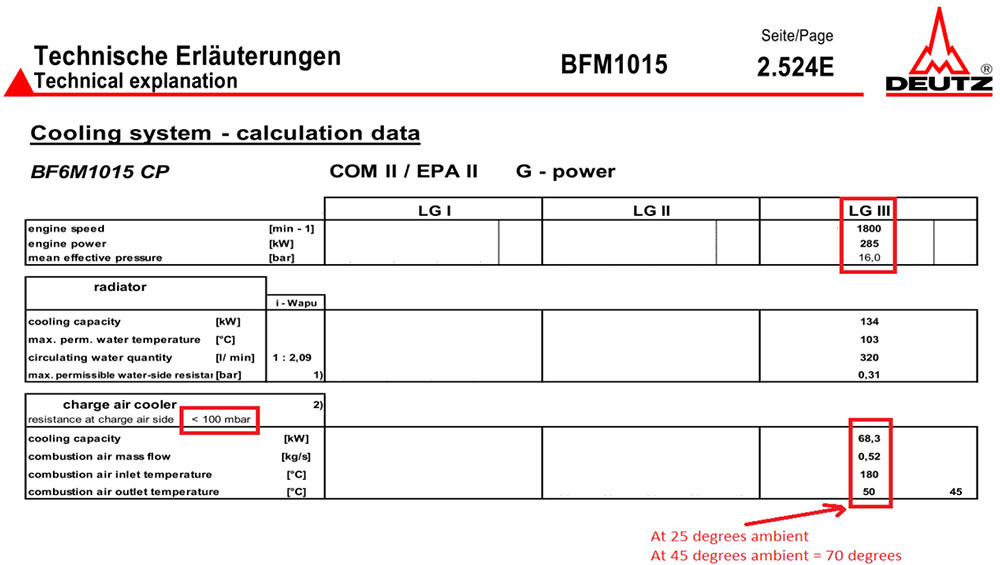

Design a water-cooled charge air cooler for a Deutz BF6M1015CP.

Engine data Deutz BF6M1015CP @ 1800 rpm 285kW:

| Charge air (turbo) | Cooling water | ||

|---|---|---|---|

| Heat | 68.3 kW | Percentage glycol | 30% |

| Mass flow | 0.52 kg/s | Volume flow | 5 m3/uur |

| Maximum workingpressure | 1.8 barg | Maximum back pressure | < 0.4 bar |

| Maximum manifold air temperture @ 40 degrees C ambient | < 70 °C | ||

| Maximum backpressure | 10 kPa |

Selected heat exchanger: GLH150

These copper brazed heat exchangers in Alfa Laval’s GTL range are plate coolers as commonly used in the industry and HVAC world, but with an increased distance between the plates and a dimple design for the air section to keep pressure drops very low.

Prestaties:

| Water side | Charge air side | ||

|---|---|---|---|

| Volume flow | 5 m3/uur | Mass flow | 0,52 kg/s |

| Pressure drop | 0,13 bar | Pressure drop | 5 kPa |

| Temperature in | 40 °C | Temperature in | 200 °C |

| Temperature out | 54 °C | Temperature out | 64,1 °C |

Brand Independent

E.g.: Deutz, Volvo, Caterpillar, Mitsubishi, Baudouin, John Deere, Cummins, Iveco, MTU