Remote cooling

Inleiding

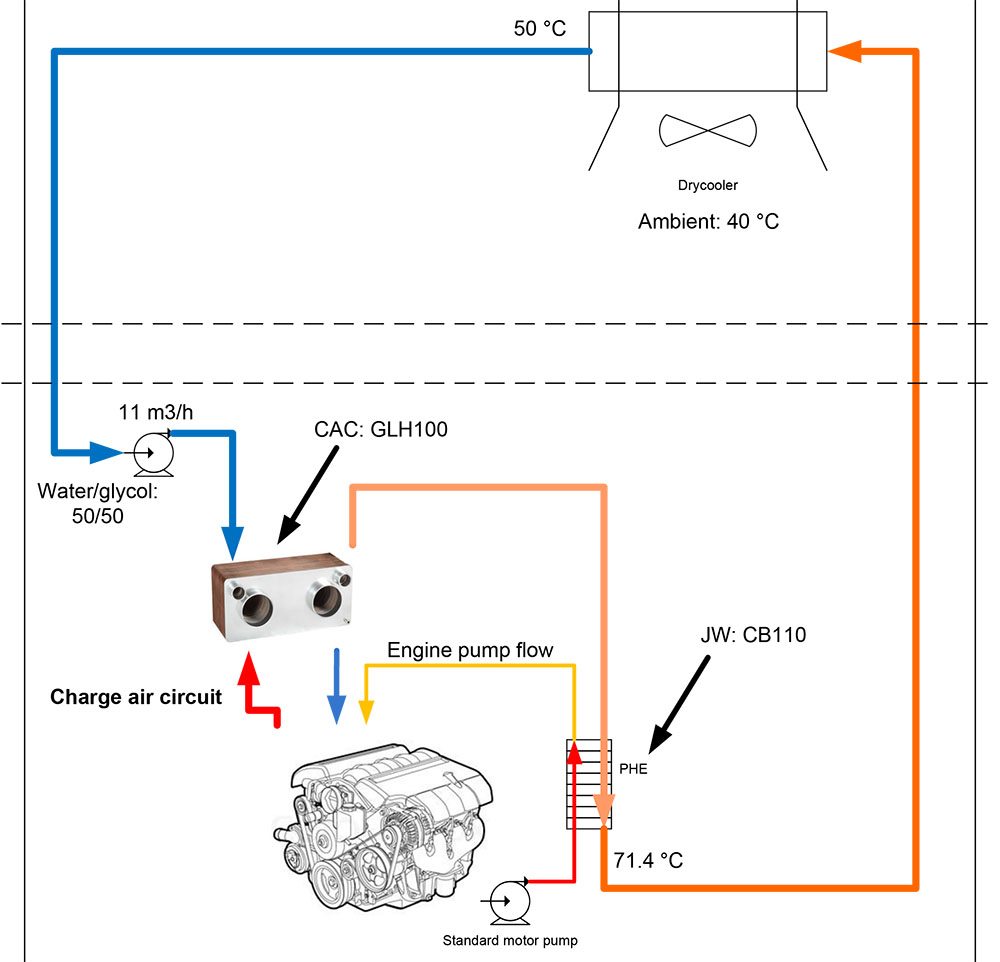

Locations of emergency generators/aggregates are not the most optimal choice in most of the projects. Due to higher capacities, the step to stage V and other wishes and requirements, it is possible that the location for the cooling is not in or near the location of the generator. Oversluizen has several solutions for remote cooling for these types of problems. All solutions are specifically calculated for the combustion engine and application.

Project: emergency power basement

Data:

- Engine: Deutz BF8M1015CP (industrial) @1500 rpm.

- Request: Making the engine suitable for remote cooling.

- Ambient condition:

- ambient temperature: 40 °C

- distance to table cooler/dry cooler: 10 meter higher

- urban environment

- 1 water circuit to drycooler.

- Scope of supply Oversluizen:

- Water cooled charge air cooler

- Plate heat exchanger for engine coolant

- Electric pump

- Expansiontank (toptank) for engine coolant circuit.

Marinising of industrial engines

With the current generation of combustion engines, both the engine coolant and the turbo air (charge air) must be cooled in order to meet the emission requirements. Due to the strict application test requirements, the accepted margins of error have been reduced to a minimum and the cooler supplier must submit calculations for this.

Engine data @ 1500 rpm 490kW:

| Engine coolant | Charge air (turbo) | ||

|---|---|---|---|

| Generated heat | 250 kW | Generated heat | 115 kW |

| Volume flow | 346 l/min | Mass flow | 0.64 kg/s |

| Maximum pressure drop | < 0.35 bar | Maximum working pressure | 2.8 barg |

| Maximum coolant temperature @ 40 degrees C ambient | < 102 °C | Maximum manifold temperature @ 40 graden C ambient | < 65 °C |

| Maximum pressure drop | 0.1 bar |

1 cooling water circuit to the roof

Pipework is expensive, but necessary. To save costs, the system is calculated in such a way that it is possible to work with 1 main cooling circuit to cool the intake air, engine water and/or generators and diesel. This is possible in 90% of the cases, whereby the possibilities of the dry cooler will often be the limiting factor.

Charge air cooling with condensate drain

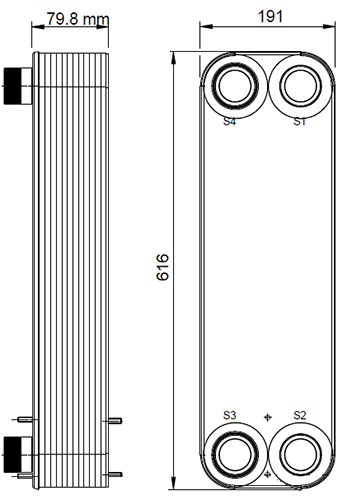

For the intercooler, Oversluizen has selected a stainless steel cooler with a maximum PED working pressure of 16 bar at 90°C. Co-designed for compressors, the Alfa Laval GLH includes an integrated condensate drain that can be used where necessary with humid inlet air.

Engine water cooling

Oversluizen has 2 variants of this:

- Suitable for seawater (plate heat exchanger with gaskets).

- Suitable for conditioned water / clean fresh water (brazed plate cooler).

- Up to maximum mechanical power: 4000 kW.

Since it concerns conditioned water, a copper brazed cooler was chosen. Taking into account the hot water from the charge air cooler, the dimensions are only 191mm by 616mm. If necessary, special couplings for easy connection can be supplied ex works.

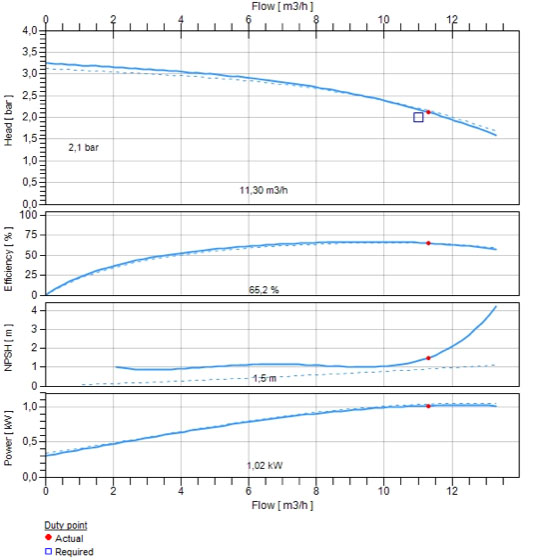

Pump selection

In addition to calculating cooling solutions, we also calculate and supply water pumps. These are usually electrically driven, but are also available as PTO driven.

In this specific case, the choice fell on a 1.1 kW electric pump (230/400V / 50Hz) with a maximum head of 21 meters at 11 m3/h.

Brand Independent

O.a.: Deutz, Volvo, Caterpillar, Mitsubishi, Baudouin, John Deere, Cummins, Iveco, MTU