Maritime off-shore cooling solutions

Calculation

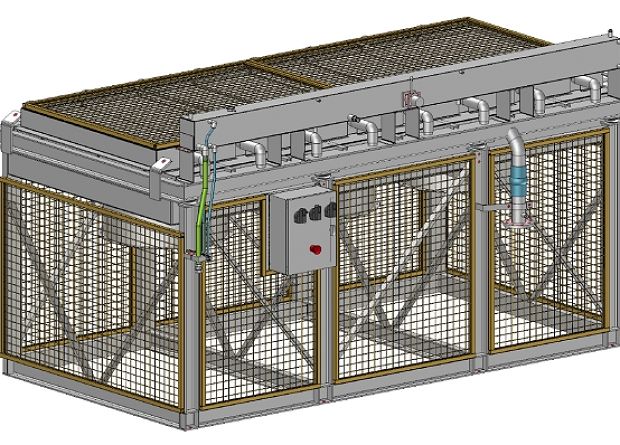

This horizontal off-shore table unit, built from elements needs to be suitable for salty air at sea, in addition to easy to repair and replace during operation. This set, which has been soundproofed, was installed on the deck of this suction cuttler, in which the materials are of such nature that can withstand the salty air, high wave impact and high ambient temperatures.

Low noise production

The noise production had to be so low that the unit, which is located near the crew, would not lead to any nuisance. In addition it needed to be deployable worldwide. In order to reduce the noise production, dense cooling blocks were selected and in order to guarantee deployability, separate elements were selected that can be exchanged and / or detached separate from each other

After approval of the customer, engineering and sales initiate a file transfer to the work preparation department, which establishes a plan of approach together with the drawing department, in order to identify any issues at an early stage.

Design department

Based on the specific customer demands and the calculations performed, a basic design is modeled in 3D.

During the design phase, we will regularly review the details of the design, possibly through *.step files which can be integrated by the client in the bigger picture. Based on experience, gained with renowned offshore companies, Oversluizen has introduced its own manufacturing standard, to be complemented with the specific desires of the customer. This includes Atex zone 1 and 2 and ship certification and own coating procedure according to Lechler

Welding

Welding is performed, according to the prescribed standards, performed by our own certified welders. This, combined with quality materials, possibly fitted with a 3Mb certification, guarantees the customer a high quality product.

As one of few companies in Europe, Oversluizen has the EN ISO 9606-2 Certificate, the highest and most strict quality- and welding requirements in the field of coolers.

End finishes

The following end finishes in this project were conducted as follows; Frame : fully hot dip galvanized + 2 layers epoxy primer + 2 component final layer, Plating : 2 layer epoxy primer

Composition 2 layers 2 component final layer

Off-shore

Cutterzuiger

Engine details: Caterpillar 3512b Marine motor

Electric power: 1257kW bij 1500 RPM

- Radiator for engine water 2009

- Radiator for water-cooled turbo air cooler/charge air cooler

- Fuel cooler

- Expansion tank

- Fans

- Electric motors

Conditions

- Ambient temperature of 45 degrees Celsius

- Sound power of 75 dB(A)

- Stainless steel Electric motors

- Downtime heating

- SPM-control

- Bureau Veritas certification up to 96% R.V. at 50 degrees Celsius

- Frame hot dip galvanized