High efficiency – small size

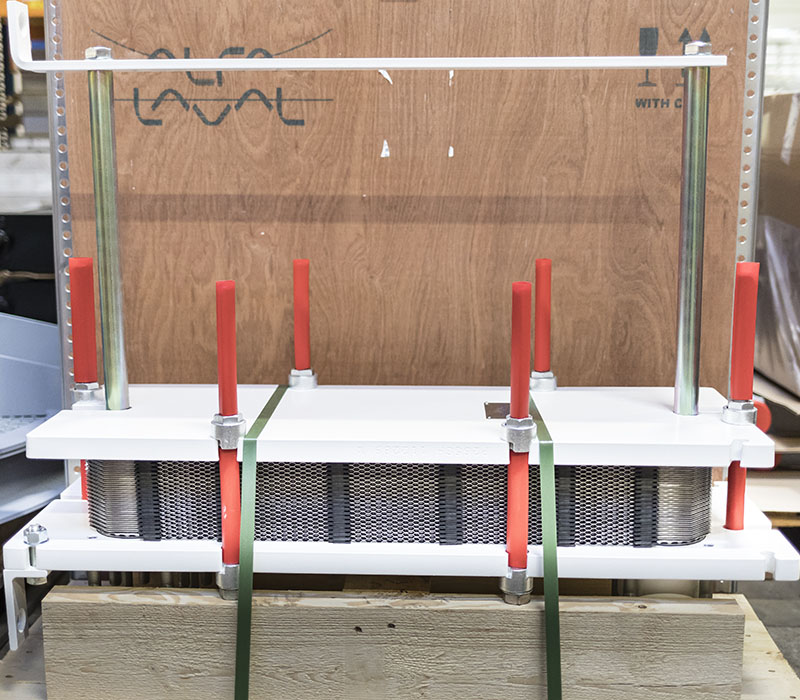

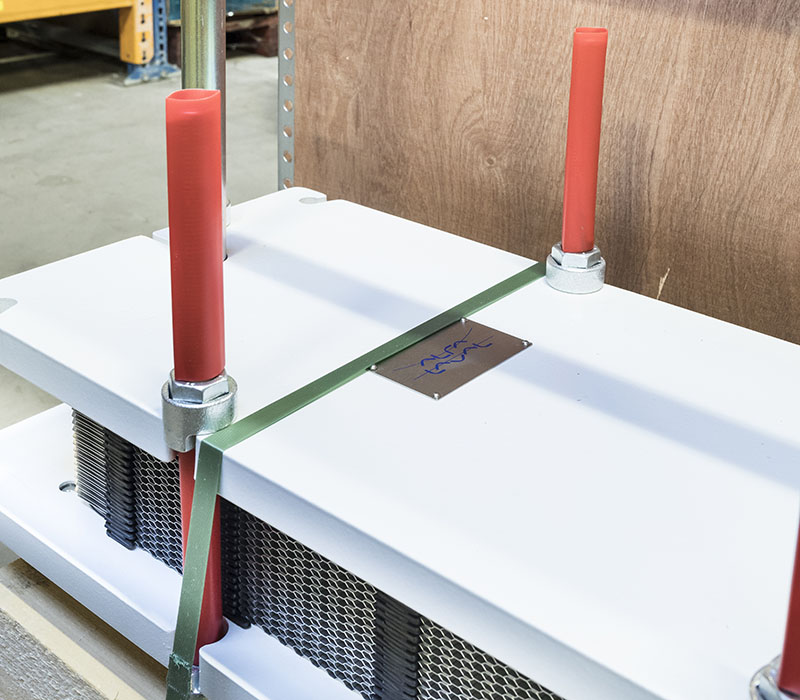

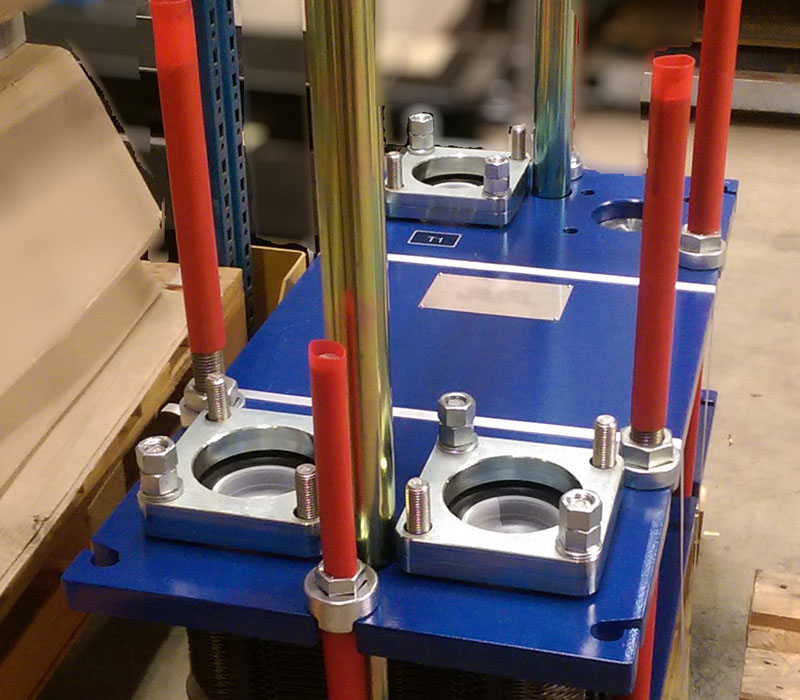

Due to this high efficiency, the dimensions of these coolers are relative small. The plate coolers supplied by Oversluizen can be fitted with practical clip-on gaskets, which can be removed, cleaned and reused during cleaning. They are also easy to disassemble when replaced. The majority of the plates are carried out in the materials

Stainless steel 304, stainless steel 316 or Titanium.

Tripple flow

Heat exchangers are often engineered for the cooling of 1 medium, so that a possible second medium often requires a separate cooler. Oversluizen calculates triple flow coolers that can cool 2 different media within 1 frame with 1 cooling medium (eg seawater). For such calculations, please contact us at sales@oversluizen.com.

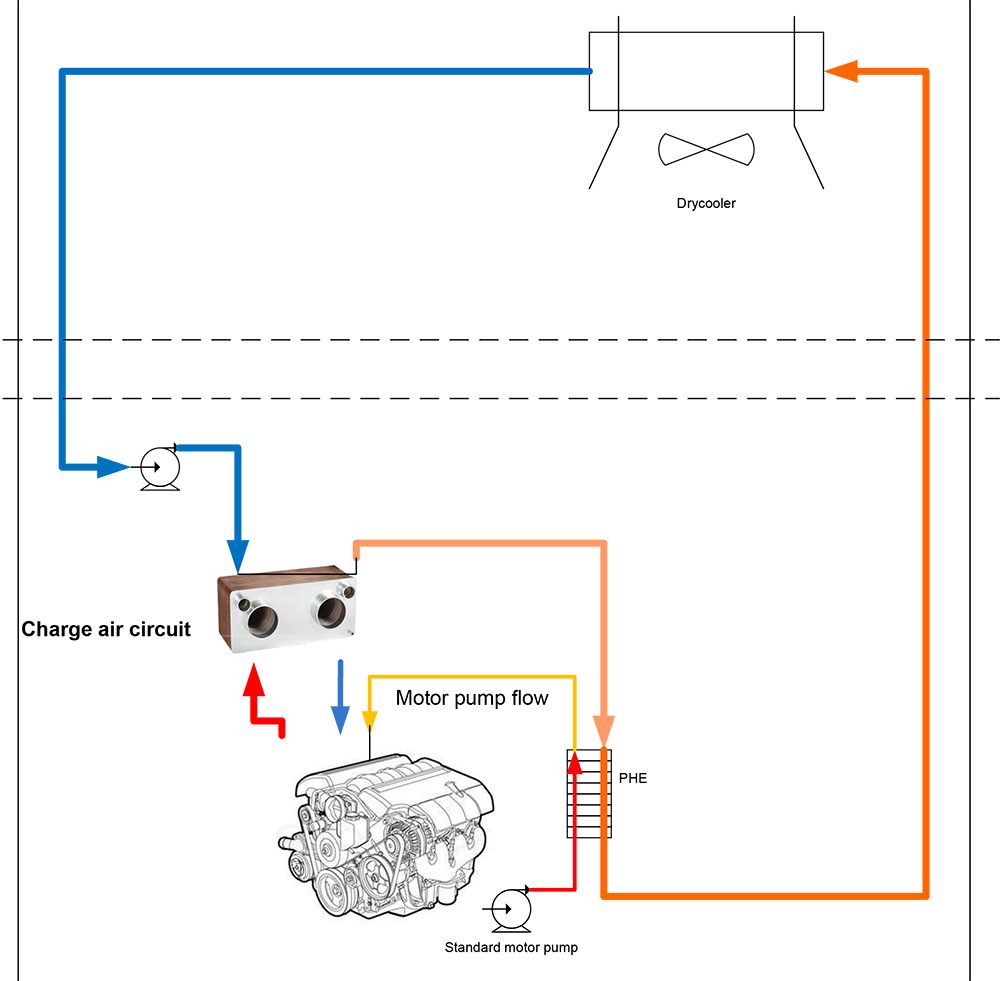

Decentralized cooling

A frequently used application is the remote cooling of engines (remote cooling). For this, a dry cooler/drycooler is placed at a greater distance from the combustion engine, many times the distance is too far that the water-side resistance becomes higher than the pump of the combustion engine can handle. This could include a basement with emergency power generators, the cooling of which can only be placed on the roof. In this case, an industrial engine with an air-cooled intercooler can be equipped with a water-cooled charge air cooler (See GTL) and a plate heat exchanger for the engine water. This creates an extra circuit in which a separate pump can be placed, which is explained for the application.